In the fast-paced world of modern media production, a well-organised schedule is the backbone of any successful project. It’s the critical difference between delivering on time and on budget versus facing costly delays and operational chaos. But with so many methodologies available, choosing the right framework for your studio or company can be a challenge. This guide moves beyond abstract theory to provide a deep strategic analysis of six essential examples of production schedules.

We'll dissect each method, exploring its unique strengths, weaknesses, and ideal applications within real-world production and post-production workflows. At its core, smarter production planning is about a constant drive for improving operational efficiency across every department, from initial concept to final delivery.

This article delivers actionable takeaways you can implement immediately. From the comprehensive scope of a Master Production Schedule to the agile flexibility of Kanban boards and the visual clarity of Gantt charts, you will gain the insights needed to master your workflow. We will explore the methods that top studios and manufacturers use to streamline their processes, enhance collaboration, and stay ahead of the competition. Let’s dive into the models that can transform your production planning from a necessary chore into a powerful strategic advantage.

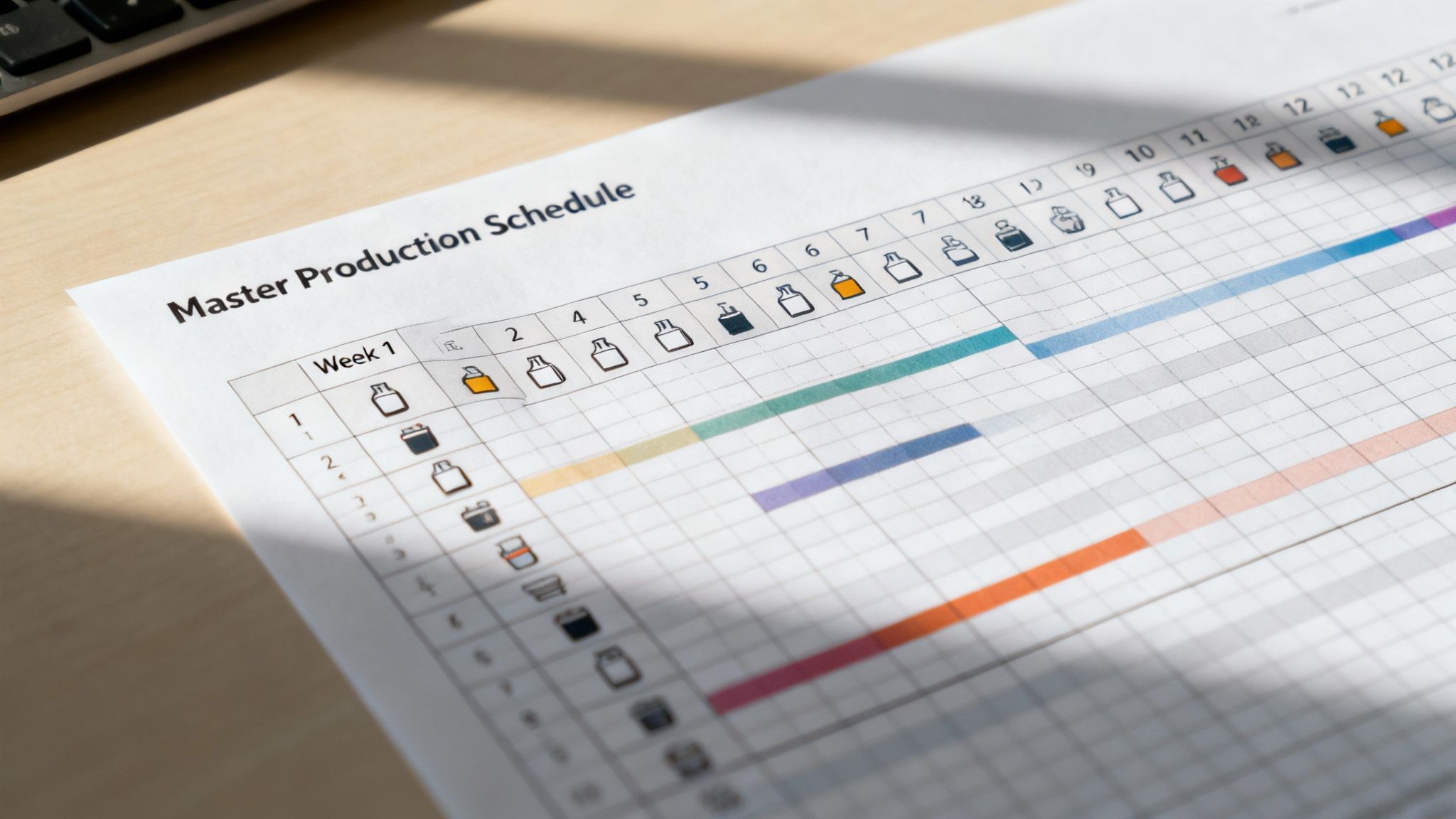

1. Master Production Schedule (MPS)

A Master Production Schedule (MPS) is the central planning document that dictates what will be produced, in what quantities, and by when. It acts as the definitive agreement between sales and production, translating broad business plans and demand forecasts into specific, tangible production targets for individual end products. This schedule is the engine that drives detailed material requirements planning (MRP), capacity planning, and shop floor scheduling.

Unlike a high-level production plan, an MPS is specific and actionable, typically looking 8-12 weeks into the future. It’s a crucial tool for stabilising the production environment by creating a firm, yet flexible, plan that all departments can align with. To dive deeper into how this foundational document fits into broader planning, explore these comprehensive examples of production schedules.

Strategic Analysis: The MPS in Action

The power of the MPS lies in its ability to balance customer demand with production capacity. For instance, Toyota’s renowned production system heavily relies on a stable MPS to synchronise its global assembly lines, ensuring just-in-time delivery of components and preventing costly overproduction. Similarly, Dell Computers uses a sophisticated MPS to manage its configure-to-order model, allowing for customer customisation while maintaining efficient assembly line flow.

In media and post-production, an MPS could dictate the final deliverables for a major film or television series. It would schedule the completion of specific outputs like the final colour grade for theatrical release, the sound mix for streaming platforms, and the VFX renders for international versions, ensuring all assets are ready for their respective distribution deadlines.

Actionable Takeaways for Implementation

To effectively implement an MPS in your workflow, consider these key tactics:

- Establish Planning Time Fences: Create clear rules for when schedule changes are permissible. A "frozen zone" (e.g., the next 1-2 weeks) should have no changes allowed, a "slushy zone" (e.g., weeks 3-6) might allow changes with approval, and an "open zone" (beyond 6 weeks) can be more flexible.

- Involve Cross-Functional Teams: The MPS should not be created in a silo. Involve representatives from sales, marketing, finance, and production to ensure the plan is both realistic and aligned with overall business objectives.

- Align with S&OP: Ensure your MPS is a direct output of your Sales and Operations Planning (S&OP) process. This top-level alignment guarantees that production targets support the broader financial and strategic goals of the organisation.

- Regular Review Cadence: The MPS is a living document. Establish a regular, disciplined schedule for reviewing and updating it to reflect actual sales, production performance, and changing market demands.

2. Kanban Production Schedule

A Kanban production schedule is a visual, pull-based system designed to manage workflow and limit work-in-progress (WIP). Popularised by Toyota, it uses visual signals, often cards or digital boards, to trigger actions in the production process. Instead of pushing work forward based on a forecast, Kanban pulls work through the system only when there is capacity, responding directly to actual demand from downstream processes.

This method excels at preventing overproduction, reducing bottlenecks, and improving flow efficiency. It’s a dynamic, self-regulating system that provides transparent insight into every stage of a workflow. To see how this flexible approach compares to more rigid frameworks, it's useful to review various examples of production schedules and their specific applications.

Strategic Analysis: The Kanban in Action

The core strength of Kanban is its focus on visual management and continuous flow. Toyota revolutionised automotive manufacturing by using physical Kanban cards on the factory floor to signal when a part needed replenishment, creating its iconic just-in-time system. Similarly, fast-fashion giant Zara uses Kanban principles to move designs from concept to shop floor in weeks, pulling new inventory based on real-time sales data from its stores.

In post-production, a Kanban board is invaluable for managing complex VFX or animation pipelines. A shot might move visually from a "To Do" column through "Modelling," "Texturing," "Animation," and "Compositing" to "Done." This allows the Head of Post-Production to instantly see where bottlenecks are forming (e.g., too many shots piling up in the "Animation" column) and reallocate artists to clear the blockage, ensuring a smooth, continuous flow of work toward final delivery.

Actionable Takeaways for Implementation

To effectively implement a Kanban schedule in your workflow, consider these key tactics:

- Visualise the Workflow: Map out every step of your production process into distinct columns on a physical or digital board. This creates a shared understanding of how work moves from start to finish.

- Establish WIP Limits: This is the most crucial step. Set explicit limits on how many tasks can be in any given column at one time. This prevents teams from becoming overloaded and exposes hidden bottlenecks in your process.

- Manage Flow: Focus on monitoring the movement of tasks through the system, not on managing individual people. The goal is to identify and resolve blockers that impede a smooth, predictable workflow.

- Make Policies Explicit: Clearly define the rules for moving a task from one column to the next. For example, what criteria must be met for a VFX shot to be considered "Done" in the compositing stage and ready for review?

- Implement Feedback Loops: Hold regular, brief stand-up meetings around the Kanban board to discuss progress, identify impediments, and synchronise the team's efforts for the day.

3. Gantt Chart Production Schedule

A Gantt chart is a powerful project management tool that visually represents a production schedule over a specific timeline. Popularised by Henry Gantt in the early 20th century, this horizontal bar chart maps out every task, its duration from start to finish, and the dependencies between them. It offers a clear, at-a-glance overview of an entire project, making it indispensable for coordinating complex, multi-stage productions.

This visual format excels at tracking progress, allocating resources, and identifying the critical path-the sequence of tasks that determines the project's total duration. In media and post-production, its ability to manage overlapping activities and tight deadlines is invaluable. To see how Gantt charts fit into a larger ecosystem of planning documents, consider these other examples of production schedules.

Strategic Analysis: The Gantt Chart in Action

The true strength of the Gantt chart lies in its clarity and ability to manage dependencies. In film production, a studio uses a Gantt chart to schedule every phase from pre-production (casting, location scouting) to filming and post-production (editing, VFX, sound mixing). A delay in securing a filming location (a predecessor task) visibly pushes back the entire shooting schedule, allowing producers to react and re-plan immediately.

Similarly, an aerospace manufacturer like Lockheed Martin relies on incredibly detailed Gantt charts to coordinate the production of thousands of components for a single aircraft. The completion of the fuselage assembly is dependent on the prior delivery of cockpit electronics and wing structures. The Gantt chart visualises these complex interdependencies, ensuring that every sub-assembly team works in perfect synchronisation, preventing bottlenecks and costly delays on the main assembly line.

Actionable Takeaways for Implementation

To integrate Gantt charts effectively into your production workflow, focus on these practical tactics:

- Identify the Critical Path: Always determine and highlight the critical path on your chart. This sequence of dependent tasks has zero slack, meaning any delay directly impacts the final delivery date. This tells your team exactly where to focus their attention to prevent schedule overruns.

- Use Colour Coding Consistently: Assign specific colours to different teams (e.g., blue for VFX, green for sound), task statuses (e.g., red for delayed, green for complete), or resource types. This creates a visual language that allows stakeholders to understand the project status instantly.

- Break Down Large Projects: Avoid creating an overwhelming chart with hundreds of minor tasks. Decompose a large project, like a feature film's post-production, into manageable phases or "work packages" such as "Picture Lock," "VFX Integration," and "Final Sound Mix."

- Update Progress Regularly: A static Gantt chart is a useless one. Establish a cadence for updating task progress (e.g., daily or weekly stand-ups) to ensure the chart remains a credible and accurate source of truth for the entire team.

4. Forward and Backward Scheduling

Forward and backward scheduling represent two fundamental methods for timing production activities, each starting from a different anchor point. Forward scheduling begins from the earliest possible start date (e.g., when materials arrive) and schedules tasks sequentially to determine the project's earliest completion date. Conversely, backward scheduling starts from a required due date and works in reverse to calculate the latest possible start date for each task, ensuring on-time delivery.

These two approaches are not mutually exclusive; modern production environments often use a hybrid model. This strategic combination allows planners to balance resource efficiency with deadline commitments, making it one of the most versatile examples of production schedules. The choice between them dictates the entire flow of operations, from material procurement to final delivery, and is a cornerstone of effective planning. For a deeper understanding of how these methods integrate into larger workflows, explore the principles of effective project planning.

Strategic Analysis: The Methods in Action

The power of these scheduling methods lies in their contextual application. A make-to-order furniture manufacturer, for instance, will use backward scheduling from the customer's promised delivery date to define the entire production timeline, from wood cutting to final finishing. This ensures customer commitments are the primary driver of the schedule. In contrast, a semiconductor fabrication plant uses forward scheduling, starting the moment a silicon wafer is ready, to maximise the utilisation of its incredibly expensive, 24/7 machinery.

In post-production, a VFX studio might use backward scheduling for a blockbuster film with a non-negotiable cinematic release date. They would work backwards from the final delivery deadline to schedule key milestones like final renders, compositing, and client reviews. Simultaneously, they might use forward scheduling for an internal R&D project to develop a new visual effect, starting as soon as an artist is available and letting the completion date be determined by the process itself.

Actionable Takeaways for Implementation

To effectively implement forward and backward scheduling in your workflow, consider these key tactics:

- Use Backward for Deadlines: Prioritise backward scheduling for any project with a firm, client-driven, or market-driven deadline. This method inherently builds the schedule around meeting that critical date.

- Use Forward for Efficiency: Apply forward scheduling when the goal is to maximise resource utilisation or to produce make-to-stock inventory. This approach gets work started as soon as possible, minimising idle time for machinery and personnel.

- Integrate Realistic Buffers: Whether scheduling forward or backward, always incorporate buffer time between critical tasks. This protects the schedule from unforeseen delays in rendering, client feedback, or technical issues without jeopardising the final delivery date.

- Combine with Capacity Planning: A backward schedule is only useful if it's achievable. Always validate the timeline against your team's and equipment's actual capacity to ensure the calculated start dates are realistic and not just theoretical.

5. Finite Capacity Scheduling (FCS)

Finite Capacity Scheduling (FCS) is a highly realistic approach that generates production schedules by respecting the actual, finite limitations of all resources. Unlike simpler methods that might assume unlimited capacity, FCS accounts for real-world constraints such as machine availability, labour skills, shift patterns, and maintenance downtime. It creates a detailed, achievable plan that prevents overloading workstations and ensures no resource is scheduled beyond its proven capacity.

This advanced method often uses sophisticated algorithms to sequence jobs optimally, considering factors like setup times, tool availability, and material flow. FCS is the bridge between a high-level plan and what can genuinely be executed on the shop floor, making it one of the most practical examples of production schedules for complex operations. For a deeper understanding of how this links to asset allocation, see this guide on effective resource management.

Strategic Analysis: The FCS in Action

The core strength of FCS is its ability to create schedules grounded in reality, which is crucial in capital-intensive industries. For instance, semiconductor giant Intel uses FCS to manage its complex wafer fabrication plants. Each piece of equipment is a multi-million-pound asset, and FCS ensures its utilisation is maximised by sequencing production runs to minimise changeover times while adhering to strict processing constraints.

Similarly, in the aerospace industry, Airbus employs FCS to coordinate the assembly of an A380, a process involving thousands of tasks across multiple stations with limited specialist tooling and skilled technicians. FCS ensures that a bottleneck at one station doesn't create an unrealistic schedule for subsequent assembly stages. In post-production, a VFX studio could use FCS to schedule render farm usage, ensuring high-priority shots for a blockbuster film are rendered without overloading the servers, while simultaneously allocating remaining capacity to projects with more flexible deadlines.

Actionable Takeaways for Implementation

To successfully deploy Finite Capacity Scheduling in your workflow, consider these key tactics:

- Accurate Master Data: The quality of an FCS schedule depends entirely on the accuracy of the input data. Ensure your system has precise information on machine capacities, processing times, setup times, and labour skill sets.

- Start with a Pilot Area: Rather than a full-scale, disruptive rollout, test FCS in a single department or on a specific production line. This allows you to refine the model, validate the data, and demonstrate value before expanding.

- Integrate with Real-Time Data: Connect your FCS system to shop floor data collection systems (like MES). This creates a feedback loop, allowing the schedule to be dynamically updated based on actual progress, machine breakdowns, or delays.

- Establish Clear Priorities: An FCS system needs to know what to optimise for. Define clear business rules and priorities, whether it's minimising setup times, meeting on-time delivery dates, or maximising the throughput of a specific bottleneck resource.

6. Drum-Buffer-Rope (DBR) Schedule

A Drum-Buffer-Rope (DBR) schedule is a production methodology derived from the Theory of Constraints (TOC), popularised by Dr. Eliyahu Goldratt in his book, The Goal. It organises the entire production flow around the system's single biggest constraint or bottleneck. This approach prevents overproduction and focuses all improvement efforts where they will have the greatest impact on overall throughput.

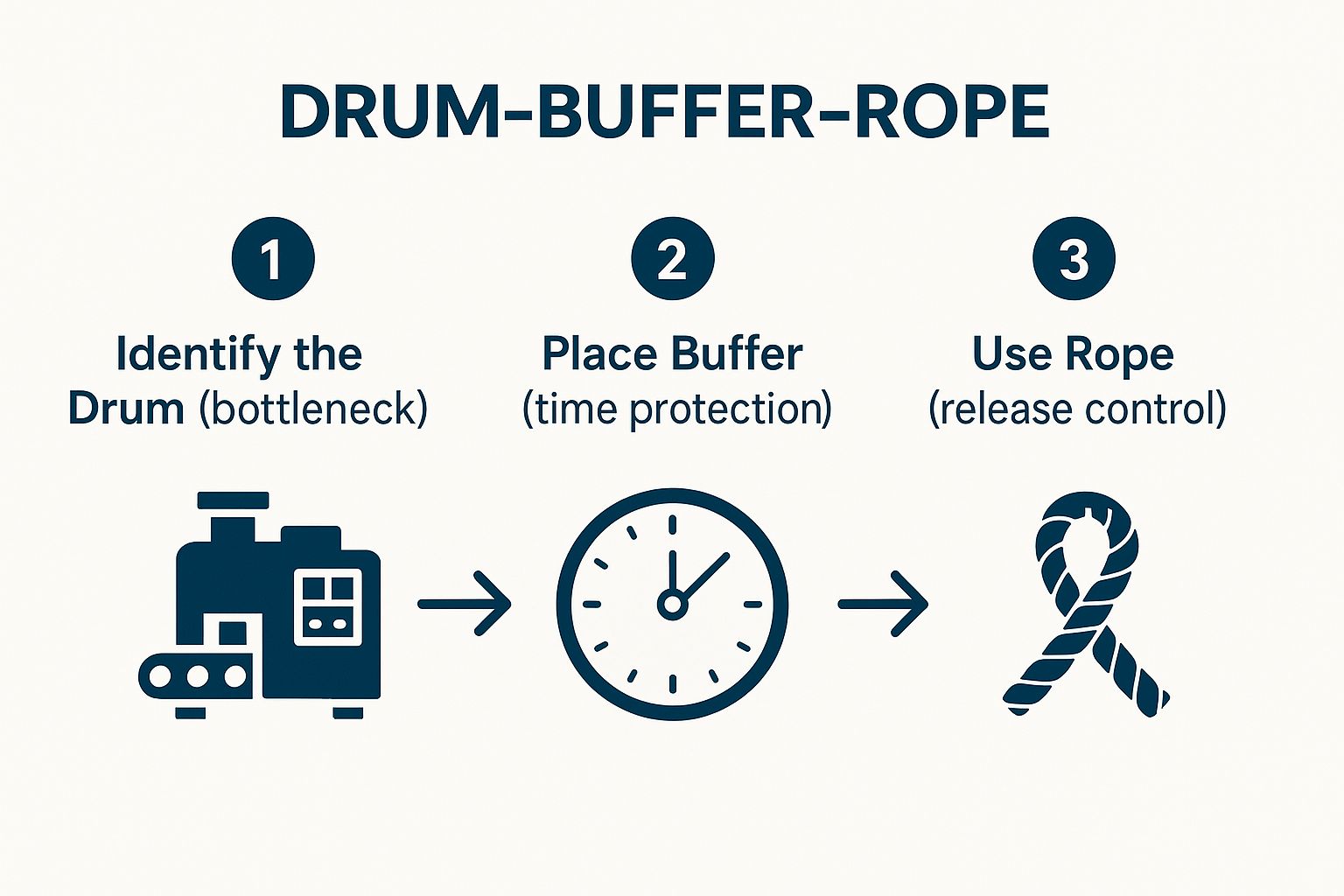

The system is defined by three core components. The 'drum' is the bottleneck resource, which sets the pace for the entire operation. The 'buffer' is a strategic amount of time-based protection placed before the drum to ensure it is never starved of work. Finally, the 'rope' is a communication signal that pulls new work into the system at the exact pace of the drum, synchronising the entire workflow to the constraint's capacity.

The following diagram illustrates this simple yet powerful three-step process for implementing DBR.

This process flow visualises how identifying the drum, protecting it with a buffer, and controlling work release with a rope creates a synchronised and efficient system. To dive deeper into how this foundational document fits into broader planning, explore these comprehensive examples of production schedules.

Strategic Analysis: The DBR in Action

The power of DBR lies in its elegant simplicity and focus. For example, General Motors famously implemented DBR in its transmission plants, leading to significant improvements in output and reductions in inventory. Similarly, Delta Faucet used the methodology to drastically improve its delivery performance and free up working capital by optimising its production flow around key constraints.

In a post-production environment, the 'drum' might be a specific high-end colour grading suite, a senior VFX artist, or the final sound mixing stage. A DBR schedule would ensure this bottleneck resource is always supplied with ready-to-work material (the buffer) and that new projects (like dailies processing or initial edits) are only started when the constraint has the capacity to eventually handle them (the rope). This prevents lower-priority tasks from consuming resources and creating downstream chaos.

Actionable Takeaways for Implementation

To effectively implement a DBR schedule in your workflow, consider these key tactics:

- Accurately Identify the Constraint: The 'drum' is not always the most expensive machine or the busiest person; it is the resource that limits the entire system's output. Use data to find your true bottleneck.

- Size Buffers Based on Variability: Do not base your time buffer on average lead times. Instead, size it to protect the drum from the realistic, worst-case delays and disruptions that occur in your upstream processes.

- Use Buffer Management for Prioritisation: Monitor how much of the buffer is being consumed for each job. Jobs that have penetrated the buffer deepest (are closest to starving the drum) become the highest priority for everyone upstream.

- Control the Rope: The most crucial rule of DBR is to never release work into the system faster than the constraint can process it. This prevents work-in-progress from piling up and obscuring the real priorities.

Comparison of 6 Production Scheduling Methods

| Schedule Type | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Master Production Schedule (MPS) | High – demands detailed data accuracy and ongoing updates | Moderate to high – requires integration with MRP & capacity | Clear production targets, better coordination, improved customer service | Manufacturing with stable product lines and forecastable demand | Provides measurable metrics, aids capacity planning |

| Kanban Production Schedule | Low to moderate – simple visual system but requires cultural change | Low – minimal inventory, visual signals, WIP limits | Reduced inventory, flexible response to demand, waste minimization | Lean manufacturing, just-in-time, repetitive production | Highly flexible, empowers workers, reduces lead times |

| Gantt Chart Production Schedule | Moderate – requires task breakdown and updating, can get complex | Moderate – resource assignment and progress tracking | Visual timeline clarity, task dependencies visibility | Project-based, job shops, custom and complex production | Intuitive overview, excellent for communication |

| Forward and Backward Scheduling | Moderate – requires accurate timing and processing data | Moderate – needs resource and material availability data | Optimized resource use (forward), guaranteed deadlines (backward) | General manufacturing with varying priorities | Systematic, helps identify shortages, flexible application |

| Finite Capacity Scheduling (FCS) | High – sophisticated algorithms, data, and software needed | High – detailed capacity and constraint data | Realistic schedules, bottleneck identification, throughput improvement | Complex manufacturing with tight capacity constraints | Maximizes utilization, reduces WIP, proactive control |

| Drum-Buffer-Rope (DBR) Schedule | Moderate – requires accurate constraint identification and buffer tuning | Moderate – focuses on bottleneck resource and buffers | Throughput maximization, lead time reduction, inventory cut | Environments with clear bottlenecks and prioritized throughput | Simplifies scheduling, focuses improvement on constraint |

Choosing Your Framework: A Strategic Approach to Scheduling

As we have explored, the world of production scheduling is not about finding a single, perfect template. Instead, it’s about strategic selection. The diverse examples of production schedules detailed in this article, from the broad oversight of a Master Production Schedule (MPS) to the constraint-focused logic of the Drum-Buffer-Rope (DBR) method, each offer a unique framework for managing complexity and driving efficiency.

Your project's success hinges on choosing the model that aligns with your specific operational reality. A fast-paced VFX studio managing dozens of artists and intricate dependencies will find immense value in the detailed, visual timeline of a Gantt chart. In contrast, a dubbing studio processing a high volume of similar, repeatable tasks might thrive under the lean, pull-based system of Kanban.

Key Strategic Takeaways

The fundamental lesson is to analyse before you implement. Before adopting any single method, critically assess your studio’s core challenges and objectives.

- Identify Your Primary Constraint: Is it artist availability (Finite Capacity Scheduling), a specific bottleneck in your pipeline (DBR), or overall project deadlines (Backward Scheduling)? Your primary constraint should heavily influence your choice.

- Match the Model to the Workflow: Don’t force a rigid, long-term Gantt chart onto a highly agile and unpredictable creative process. Align the scheduling tool’s philosophy with your team’s natural way of working.

- Embrace Hybrid Approaches: The most effective systems often borrow elements from multiple models. You might use a high-level MPS for long-range planning while managing day-to-day tasks with a Kanban board, creating a powerful, multi-layered approach.

Mastering these scheduling concepts is more than an academic exercise; it is the foundation of a resilient, profitable, and less chaotic production environment. A well-chosen and properly implemented schedule reduces artist burnout, minimises costly delays, and provides the clarity needed to make proactive, data-driven decisions. It transforms your workflow from a series of reactive fire-fighting exercises into a predictable, optimised, and well-organised process.

Ultimately, the right production schedule empowers your team to focus on what they do best: creating exceptional content. By moving beyond a generic calendar and adopting a strategic scheduling framework, you build a powerful competitive advantage, ensuring projects are delivered on time, on budget, and to the highest standard of quality. This strategic foresight is the hallmark of a leading post-production operation.

Ready to move beyond static spreadsheets and apply these scheduling principles in a dynamic, AI-native platform? Discover how freispace integrates the visual clarity of Gantt charts with real-time resource management and intelligent automation, purpose-built for the complex demands of modern studios. Explore how freispace can transform your production scheduling today.