In the fast-paced world of media production, a well-structured schedule is the backbone of success. It transforms complex project goals into an actionable, day-by-day plan, turning a chaotic vision into a tangible deliverable. But with so many methodologies available, from Gantt charts to Kanban boards, how do you choose the right one for your film, TV, or post-production workflow?

This guide provides a detailed breakdown of seven distinct example production schedule types. We move beyond surface-level descriptions to offer deep strategic analysis, actionable takeaways, and replicable methods for each. Our goal is to equip you with the strategic tools needed to organise your workflow, manage resources effectively, and deliver projects on time and within budget. To truly move from chaos to clarity in your creative business, it's essential to understand how to streamline operations without losing your creative spark, which is the ultimate goal of an effective production schedule.

We will explore frameworks like the Master Production Schedule (MPS), Backward Scheduling, and Level Production to help you find the perfect fit. Let's dive into the structures that power the world's most efficient creative operations.

1. Master Production Schedule (MPS)

A Master Production Schedule (MPS) is a high-level, forward-looking plan that dictates what will be produced, in what quantities, and on what timeline. It acts as the command centre for all manufacturing activities, translating broader business goals, sales forecasts, and firm customer orders into a tangible production plan. This detailed schedule serves as the primary input for crucial downstream processes like Material Requirements Planning (MRP) and Capacity Requirements Planning (CRP), ensuring resources are aligned with demand.

This example production schedule is the bedrock of organised manufacturing, popularised by pioneers like Joseph Orlicky and institutionalised by organisations like APICS. It is indispensable for companies managing complex supply chains and diverse product lines, such as Toyota coordinating global car manufacturing or Boeing orchestrating intricate aircraft assembly. The MPS provides a stable framework, preventing the chaos of reactive, last-minute production changes.

Strategic Breakdown & Analysis

An effective MPS hinges on a balance between stability and flexibility. It achieves this by creating "time fences" or zones. For instance, a "frozen zone" (typically the next 1-2 weeks) locks the schedule to prevent costly disruptions, while a "flexible zone" further out allows for adjustments based on new demand signals. This structured approach provides predictability for procurement and shop floor operations while retaining the ability to adapt.

Key Insight: The MPS is not just a schedule; it's a contract between sales, operations, and finance. It ensures that the production plan is realistic, aligned with business capacity, and supports commercial objectives, preventing departments from working in silos.

Actionable Takeaways

To implement an MPS effectively, focus on these critical tactics:

- Establish a "Frozen Zone": Define a period (e.g., two weeks) where no changes to the schedule are permitted. This stabilises procurement and manufacturing operations.

- Weekly MPS Reviews: Organise cross-functional meetings with sales, operations, and supply chain teams to review performance and update the schedule weekly.

- Align with S&OP: Ensure the MPS is a direct output of your Sales and Operations Planning (S&OP) process. This top-down alignment guarantees the production plan supports strategic business goals.

- Use Buffers for Variability: Maintain safety stock for components or finished goods with unpredictable demand to cushion against forecast inaccuracies.

2. Gantt Chart Production Schedule

A Gantt chart is a visual bar chart that illustrates a project or production schedule over time. Each horizontal bar represents a specific task or production activity, with its length corresponding to the task's duration. The chart clearly displays task dependencies, milestones, and progress, making it one of the most popular and intuitive tools for managing complex workflows. It translates a list of activities into a clear, timeline-based view, helping teams identify potential bottlenecks and understand the critical path.

This example production schedule is a cornerstone of modern project management, first popularised by Henry Gantt in the 1910s and now digitised through software like Microsoft Project, Smartsheet, and Asana. It is indispensable for industries with sequential, dependent tasks. For example, Marvel Studios uses Gantt charts to coordinate intricate film shooting schedules, from pre-production to post-production, while SpaceX employs them to manage rocket component manufacturing and assembly timelines, ensuring every part is ready for integration at the right moment.

Strategic Breakdown & Analysis

An effective Gantt chart excels at visualising dependencies, where one task cannot begin until another is completed. This visual linkage is critical for identifying the "critical path" - the longest sequence of dependent tasks that determines the minimum time to complete the project. By focusing on this path, managers can allocate resources more effectively and proactively address activities that could cause major delays. It transforms a complex production plan into a universally understood visual roadmap. You can learn more about how Gantt charts are used in detailed project planning and resource management.

Key Insight: The true power of a Gantt chart lies in its ability to communicate complex timelines simply. It provides a single source of truth that aligns diverse teams, from VFX artists to sound engineers, on what needs to happen, by whom, and when, preventing miscommunication and siloed efforts.

Actionable Takeaways

To implement a Gantt chart production schedule effectively, focus on these tactics:

- Colour-Code for Clarity: Assign different colours to bars based on department, resource, or priority level (e.g., blue for VFX, green for audio post). This provides an instant visual summary.

- Establish a Review Cadence: Update progress on the chart weekly and hold brief stand-up meetings to communicate changes and address emerging risks immediately.

- Link Tasks with Dependencies: Actively define task relationships (finish-to-start, start-to-start) to create a dynamic schedule that automatically adjusts as timelines shift.

- Include Buffer Time: Add contingency time to high-risk or uncertain tasks, such as complex VFX renders or client approval stages, to build resilience into your schedule.

3. Kanban Production Schedule

A Kanban Production Schedule is a pull-based system that uses visual signals to trigger production or material replenishment only when needed. Originating from Toyota’s lean manufacturing philosophy, Kanban schedules work based on actual consumption rather than forecasts. When a downstream process consumes materials, a signal (like a card or an empty bin) is sent upstream to produce or deliver more, creating a just-in-time workflow.

This example production schedule is a cornerstone of lean operations, popularised by its creator Taiichi Ohno at Toyota and later adapted for knowledge work by David J. Anderson. It is critical for organisations that prioritise responsiveness and waste reduction, such as Dell’s build-to-order PC assembly or Zara’s fast-fashion supply chain. The Kanban system creates a highly adaptive production flow that prevents overproduction and minimises inventory carrying costs.

Strategic Breakdown & Analysis

An effective Kanban system focuses on managing workflow rather than managing workers. It visualises every stage of production, making bottlenecks immediately apparent. By setting explicit Work-in-Progress (WIP) limits for each stage, it prevents teams from being overloaded and ensures a smooth, continuous flow of value. This visualisation is key; for a deeper dive into visualising workflows and reducing bottlenecks, explore the principles of Kanban board project management. This approach shifts the focus from keeping everyone busy to consistently delivering finished goods.

Key Insight: Kanban is a system of continuous improvement (kaizen). The visual board doesn't just manage work; it exposes systemic problems like process delays, resource constraints, or quality issues, forcing teams to confront and solve them collaboratively to improve flow.

Actionable Takeaways

To implement a Kanban schedule effectively, focus on these critical tactics:

- Establish WIP Limits: Set explicit limits on how many tasks can be in any single stage of the process. This is the core mechanism for creating a pull system and preventing bottlenecks.

- Visualise the Workflow: Use a physical or digital Kanban board to map out every step of your production process. This creates a shared understanding and exposes inefficiencies.

- Implement a Pull Signal: Define clear signals (e.g., an empty container, a digital notification) that authorise the upstream process to produce the next item.

- Regularly Review and Adapt: Continuously analyse flow metrics like cycle time and lead time. Use this data to adjust WIP limits, optimise processes, and remove obstacles.

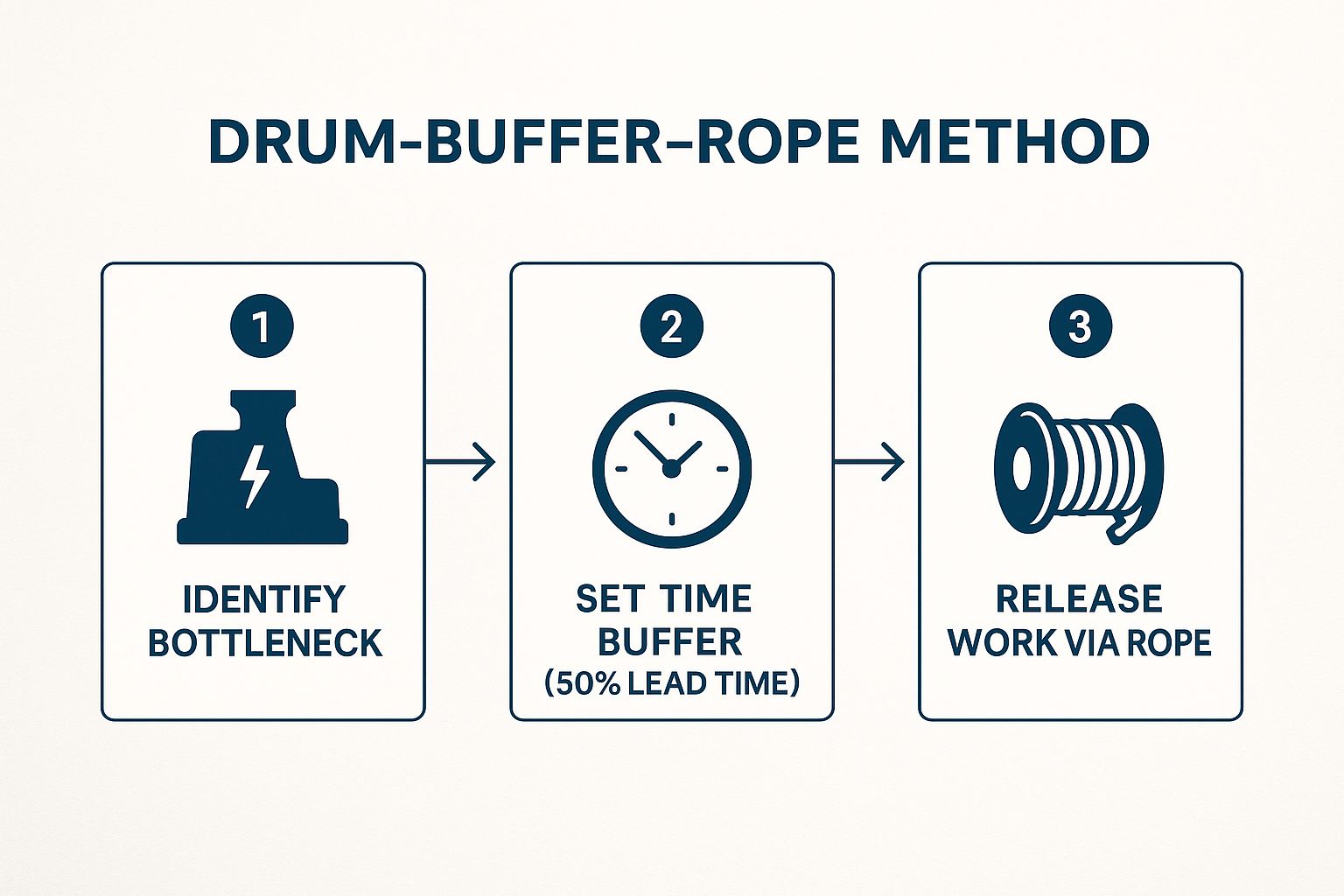

4. Capacity-Constrained Production Schedule

A capacity-constrained production schedule is designed around the limitations of bottleneck resources, which are the machines, workstations, or processes with the lowest capacity relative to demand. This scheduling approach identifies the constraint (often called the drum) and synchronises the entire production system to maximise throughput. Based on the Theory of Constraints (TOC), this method ensures the bottleneck is never idle and that non-constraint resources support its rhythm, preventing overproduction and excessive work-in-progress inventory.

This example production schedule was popularised by Dr. Eliyahu M. Goldratt in his seminal book, The Goal. It is essential for industries where a single process dictates overall output, such as Intel scheduling around photolithography equipment or a steel mill planning based on blast furnace capacity. This methodology shifts the focus from optimising individual components to optimising the flow of the entire system, leading to significant gains in throughput and efficiency.

Strategic Breakdown & Analysis

An effective capacity-constrained schedule operates on the "Drum-Buffer-Rope" (DBR) principle. The "drum" is the bottleneck's production rate, which sets the pace for the entire operation. The "buffer" is a strategic amount of time or inventory placed before the constraint to protect it from disruptions. The "rope" is the signal that releases raw materials into the system, timed perfectly to arrive at the bottleneck just when needed. This prevents upstream processes from building up unnecessary inventory.

Key Insight: The core principle is that any time lost at a bottleneck is time lost for the entire system, whereas time saved at a non-bottleneck is a mirage. By focusing all improvement efforts on the constraint, companies achieve maximum leverage and impact on overall performance.

Actionable Takeaways

To implement a capacity-constrained schedule effectively, focus on these critical tactics:

- Follow the Five Focusing Steps: Systematically Identify the constraint, Exploit it (maximise its uptime), Subordinate everything else to it, Elevate its capacity, and then Repeat the process.

- Establish Time Buffers: Place a time buffer (e.g., 50% of the average lead time) before the constraint to absorb variability from upstream processes.

- Schedule the Constraint First: Build the entire production schedule around the bottleneck. Plan its activities first, then schedule backward for preceding tasks and forward for subsequent ones.

- Avoid Local Optimisation: Discourage non-bottleneck resources from producing as fast as possible. Their role is to support the constraint, not to build excess inventory. Mastering this is a key aspect of effective resource management.

5. Backward Scheduling Production Schedule

A Backward Scheduling Production Schedule is a planning method that begins with a firm deadline, like a customer delivery date, and works backwards to determine the start date for each production task. It calculates the latest possible moment each operation can commence without jeopardising the final deadline. This approach is the cornerstone of just-in-time (JIT) and make-to-order manufacturing environments, ensuring resources are only committed as needed to meet specific commitments.

This example production schedule is a core function in modern Enterprise Resource Planning (ERP) and Advanced Planning and Scheduling (APS) systems. It is indispensable for businesses where delivery dates are non-negotiable, such as a custom furniture maker planning work based on an agreed installation date or an aerospace manufacturer scheduling complex assemblies to meet a contractual aircraft delivery deadline. The primary goal is to minimise inventory holding costs and optimise resource utilisation by delaying production until the last feasible moment.

Strategic Breakdown & Analysis

The effectiveness of backward scheduling lies in its deadline-driven focus. By calculating start times from the finish line, it automatically prioritises jobs based on their due dates, preventing less urgent tasks from consuming capacity needed for critical orders. The process meticulously accounts for every component of lead time: setup, processing, queue, and transit times for each step. This creates a highly efficient, lean production flow that is directly synchronised with customer demand.

Key Insight: Backward scheduling transforms production planning from a "push" system (making products based on forecasts) to a "pull" system (making products based on actual orders). This shift fundamentally aligns operational activities with commercial commitments, ensuring that what gets made is precisely what the customer wants, when they want it.

Actionable Takeaways

To implement a backward schedule effectively, focus on these critical tactics:

- Integrate Safety Buffers: Incorporate realistic time buffers before high-risk or bottleneck operations. This provides a cushion against unforeseen delays without compromising the final delivery date.

- Validate Capacity Constraints: After creating the backward schedule, run it against a capacity plan (finite scheduling) to ensure you have the required labour and machine availability.

- Flag Urgent Jobs: Any job whose calculated start date falls in the past should be immediately flagged as urgent. This signals an immediate need for expediting or re-prioritisation.

- Account for Logistics: Ensure that final shipping and transportation times are included as the very last step in your backward calculation to provide a true production completion deadline.

6. Level Production Schedule (Heijunka)

A Level Production Schedule, known as Heijunka in Japanese, is a lean manufacturing technique for smoothing production. It levels output by both volume and product mix over a fixed period, avoiding the inefficiencies of traditional batch production. Instead of dedicating entire days to single products, Heijunka schedules smaller, mixed quantities of different products throughout each day or week, creating a predictable and consistent workflow. This method is central to reducing Mura (unevenness) in a production system.

This example production schedule was popularised by Taiichi Ohno as a core component of the Toyota Production System. Its principles are now applied far beyond automotive manufacturing, from Herman Miller mixing furniture models on its assembly lines to pharmaceutical companies levelling the packaging of different SKUs. The goal is to create a stable, rhythmic production flow that minimises inventory, reduces lead times, and can more flexibly respond to fluctuations in customer demand without causing disruptions upstream.

Strategic Breakdown & Analysis

Heijunka's effectiveness comes from its ability to create stability in an inherently unstable environment. By breaking down large batches into smaller, more frequent production runs, it reduces the "bullwhip effect" that ripples through the supply chain. This levelling requires rapid changeovers between products, forcing teams to perfect processes like Single-Minute Exchange of Die (SMED). A visual tool, the Heijunka box, is often used to manage this, with pigeonholes representing production intervals and Kanban cards dictating the exact sequence of products to be made.

Key Insight: Heijunka transforms the production floor from a reactive, batch-driven system to a proactive, flow-based one. It is a commitment to operational discipline that forces an organisation to become more agile, as the ability to produce in small, mixed lots is the ultimate defence against demand volatility.

Actionable Takeaways

To implement a Level Production Schedule effectively, focus on these critical tactics:

- Calculate Takt Time: Determine the pace of production required to meet customer demand (available production time / customer demand). This becomes your operational heartbeat.

- Master Quick Changeovers: Implement SMED principles to drastically reduce the time it takes to switch between producing different products. This is non-negotiable for Heijunka.

- Visualise the Schedule: Use a Heijunka box or digital board to make the levelled schedule visible to everyone on the shop floor, ensuring clear communication and adherence.

- Level Volume, then Mix: Start by smoothing the total quantity of units produced each day. Once stable, begin levelling the mix of different product types within that consistent volume.

7. Finite Capacity Scheduling (FCS)

Finite Capacity Scheduling (FCS) is a sophisticated approach that generates production schedules by explicitly accounting for the genuine capacity limits of every resource, including machines, labour, and tools. Unlike infinite capacity planning, which assumes resources are limitless, FCS creates a realistic model based on actual availability, shift calendars, and maintenance downtime. This method assigns operations to specific resources at precise times, guaranteeing no resource is overloaded and all constraints are met.

This results in a feasible and executable example production schedule that reflects the real-world limitations of a manufacturing or production environment. It was popularised by advanced planning systems like Preactor (now Siemens Opcenter APS) and Asprova. Global leaders depend on it, with Siemens using it for turbine manufacturing, Lockheed Martin for aerospace components, and Johnson & Johnson for complex pharmaceutical batch scheduling. FCS provides the precision needed to manage intricate, resource-constrained operations effectively.

Strategic Breakdown & Analysis

The power of FCS lies in its reality-based simulation. By modelling constraints accurately, it prevents the creation of ambitious but unachievable plans, a common pitfall of simpler scheduling methods. The system can sequence jobs to optimise for specific goals, such as minimising changeover times or maximising on-time delivery. It considers dependencies and bottlenecks, allowing schedulers to perform "what-if" analyses to see the impact of adding a shift, expediting a job, or dealing with unexpected machine downtime.

Key Insight: FCS transforms scheduling from a reactive administrative task into a proactive strategic tool. It provides a digital twin of the shop floor, empowering managers to make data-driven decisions that directly improve throughput, reduce lead times, and enhance resource utilisation.

Actionable Takeaways

To leverage Finite Capacity Scheduling, implement these focused tactics:

- Ensure Master Data Accuracy: Before implementation, verify that all core data, including work centre capacities, routing times, and shift calendars, is precise. Inaccurate data will produce a flawed schedule.

- Establish Clear Scheduling Rules: Define the primary objectives for the schedule, such as minimising costs, maximising on-time delivery, or levelling resource load. Configure the system to optimise for these goals.

- Integrate with MES/ERP: Connect your FCS software with Manufacturing Execution Systems (MES) or ERPs for real-time feedback on job progress. This enables dynamic rescheduling based on actual performance.

- Use Time Horizons: Create a "frozen" short-term horizon to provide stability for shop floor execution and a "flexible" long-term horizon for planning and what-if scenarios.

7 Production Schedule Methods Comparison

| Production Schedule Type | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Master Production Schedule (MPS) | Medium to High (requires ERP/MRP systems; data-intensive) | High (detailed data inputs, forecasting) | Clear production priorities; optimized inventory; accurate delivery dates | Medium to large repetitive manufacturing | Visibility into priorities; supports capacity planning; integrates forecasting |

| Gantt Chart Production Schedule | Medium (software tools needed; frequent updates) | Medium (project management software) | Intuitive timeline view; shows dependencies; aids conflict identification | Project-based manufacturing, construction, one-off runs | Easy to understand; communicates schedules; facilitates what-if analysis |

| Kanban Production Schedule | Low to Medium (cultural change, training required) | Low to Medium (visual signals, WIP limits) | Reduced inventory; responsive flow; waste minimization | Stable demand repetitive manufacturing | Minimizes waste; empowers workers; quick bottleneck detection |

| Capacity-Constrained Scheduling | High (constraint identification; detailed analysis) | Medium to High (focus on bottlenecks) | Maximized throughput; reduced WIP; improved delivery performance | Complex manufacturing with clear bottlenecks | Maximizes system throughput; reduces inventory; simplifies decisions |

| Backward Scheduling | Medium (needs accurate operation times; buffer management) | Medium (coordination with capacity) | Minimal WIP; due-date alignment; early late delivery identification | Make-to-order, engineer-to-order environments | Minimizes inventory; aligns tightly to due dates; clear release timing |

| Level Production Schedule (Heijunka) | Medium to High (requires process reliability, setup improvements) | Medium (SMED capabilities, scheduling tools) | Reduced inventory; stable workflow; demand smoothing | High-volume, mixed-model manufacturing | Reduces inventory; smooths demand; balances workload |

| Finite Capacity Scheduling (FCS) | High (complex software, data accuracy critical) | High (integration with ERP, MES, resources) | Realistic, feasible schedules; maximized utilization; fewer disruptions | Complex manufacturing with multiple constraints | Accurate delivery dates; proactive bottleneck ID; maximizes resource use |

Supercharging Your Schedule: The Future is AI-Native

Throughout this guide, we have explored a diverse array of scheduling frameworks, from the high-level strategic overview of a Master Production Schedule to the granular, constraint-aware precision of Finite Capacity Scheduling. We have analysed how Gantt charts offer visual clarity for linear projects, how Kanban boards provide unparalleled agility for iterative workflows, and how techniques like Backward Scheduling ensure deadlines are always met. Each example production schedule offers a unique set of tools to tackle the complexities of modern creative and manufacturing projects.

The core lesson is clear: there is no single, perfect schedule. The optimal approach is a hybrid, one that borrows the best elements from multiple methodologies. It requires the strategic foresight of an MPS, the visual tracking of a Gantt chart, and the real-time adaptability of Kanban, all while respecting the genuine limitations highlighted by capacity-constrained models. Mastering these concepts is no longer a competitive advantage; it is a fundamental requirement for survival and growth in a fast-paced industry.

From Static Plans to Dynamic Ecosystems

The critical shift for forward-thinking organisations is moving away from static, manually updated documents towards a living, intelligent scheduling ecosystem. A traditional schedule, no matter how well-crafted, is a snapshot in time. It begins to decay the moment it is published, as unforeseen client feedback, resource unavailability, or technical hitches inevitably arise. Relying solely on these manual methods is like navigating a complex city with a paper map when real-time GPS is available.

The future of production management lies in systems that don't just record the plan but actively help to optimise it. This means embracing technology that can:

- Automate Resource Allocation: Intelligently assign tasks based on artist skill sets, availability, and project priority, eliminating manual guesswork.

- Provide Predictive Analytics: Forecast potential bottlenecks and capacity shortfalls before they derail a project, allowing for proactive adjustments.

- Integrate Departmental Data: Create a single source of truth that connects pre-production, production, and post-production, ensuring everyone is working from the most current information.

Embracing an AI-Native Approach

This is where AI-native platforms become transformative. While the principles of a Gantt chart or a Finite Capacity Schedule remain valuable, an intelligent system elevates their execution. It takes the manual, time-consuming calculations of FCS and automates them, providing instant, optimised scenarios. It enhances the visual feedback loop of Kanban with data-driven insights, suggesting workflow improvements and highlighting hidden dependencies.

By adopting an AI-powered solution, you transition from being a reactive scheduler to a strategic production manager. You spend less time wrestling with spreadsheets and more time making high-impact decisions. This evolution allows you to not just manage your production pipeline but to truly master it, ensuring every project is delivered efficiently, on budget, and to the highest standard of quality. The right example production schedule is your blueprint; intelligent technology is the engine that brings it to life.

Ready to move beyond static templates and build a truly dynamic, intelligent production pipeline? Discover how freispace leverages AI to automate resource allocation, predict bottlenecks, and give you complete control over your schedule. See the future of production management at freispace.